Oliver Harper

I am a passionate designer who likes to take a hands on approach to my projects, if you like what you see, don't hesitate to get in touch!

I am a passionate designer who likes to take a hands on approach to my projects, if you like what you see, don't hesitate to get in touch!

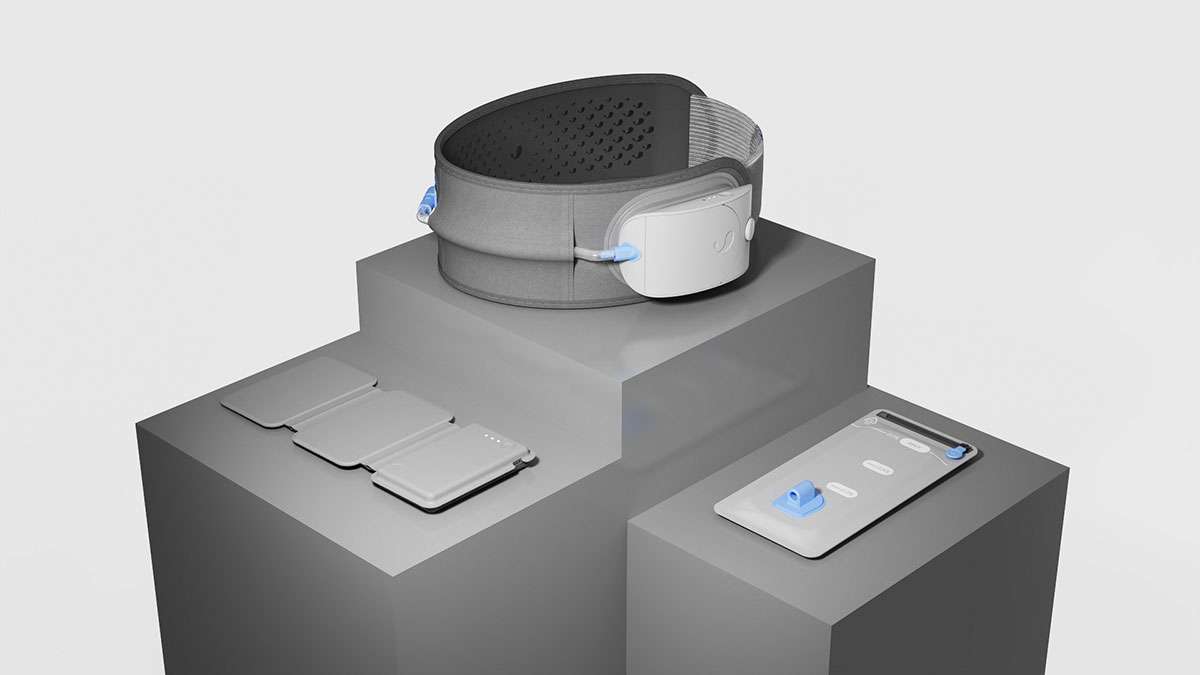

Flow empowers users to gain a level control over their stoma, transforming their mornings and eliminating the need for colostomy bags. This hands-free, stress-free device streamlines stoma irrigation, allowing ostomates to reclaim their time and independence.

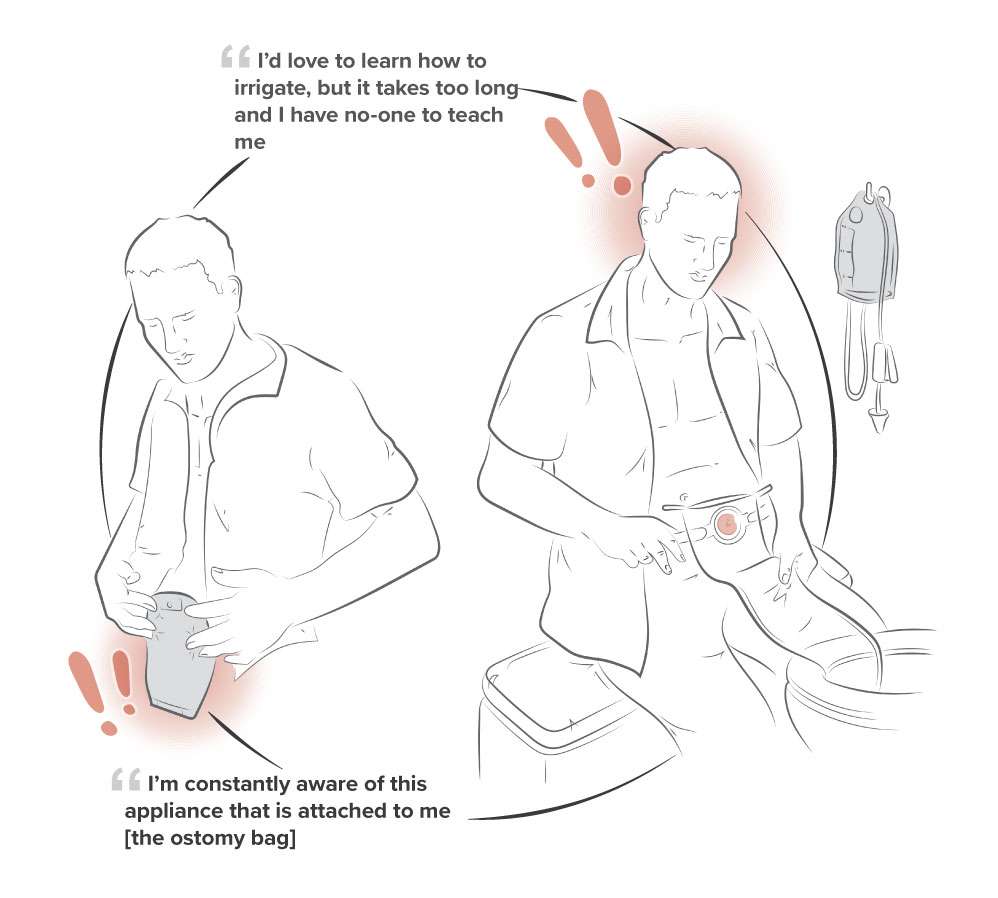

Currently, ostomates spend up to an hour each morning in the bathroom to irrigate their stoma—a crucial procedure for living without colostomy bags and avoiding leaks. Traditional products offer limited control, and with nurses often too busy to provide proper training, only about 1% of UK ostomates irrigate. Flow changes everything, making stoma irrigation accessible and efficient for everyone.

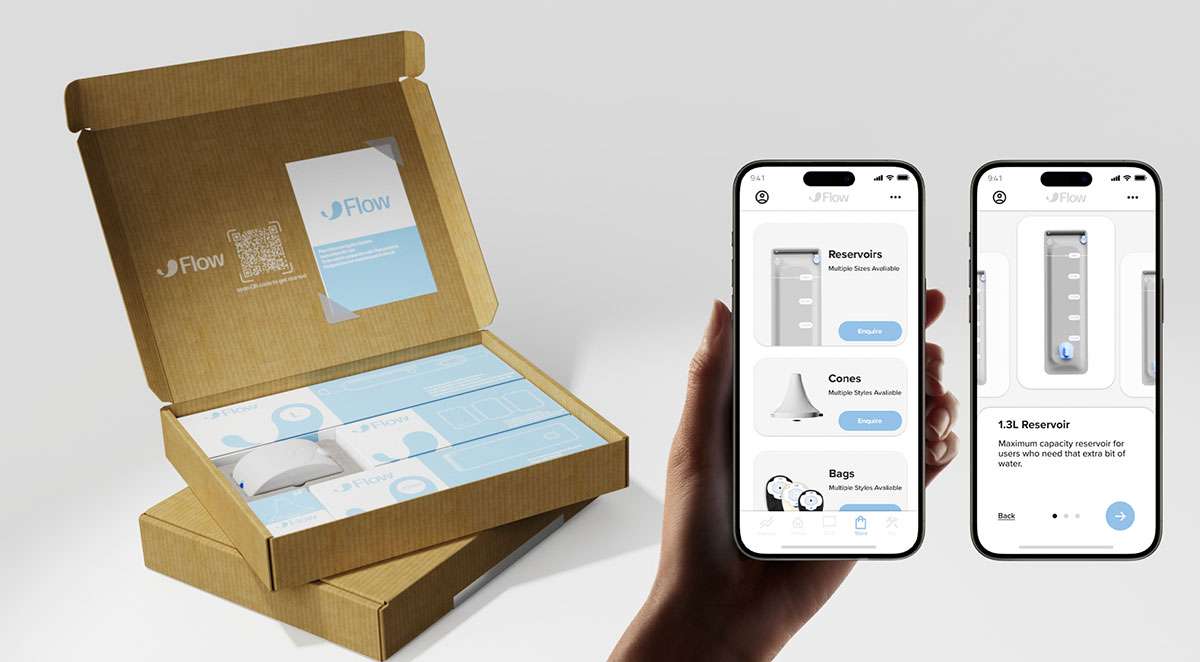

At the start of their irrigation journey, users can order a customized Flow package with the support of their Stoma Care Nurse. As disposable components require replacement, users can conveniently order new parts through the Flow companion app. This app also enables users to maintain contact with their virtual nurse and offers enhanced control over the Flow pump.

Flow consists of four main components: the belt with an integrated pump, a heating pad, and a reservoir. These elements are seamlessly incorporated into a comfortable belt, allowing users to irrigate their stoma in a controlled manner at the optimal temperature.

The internal components were meticulously chosen to create a compact solution that does not hinder the user. The use of a standard peristaltic pump allows for quick and easy replacement of perishable inner tubing by simply removing the front cover.

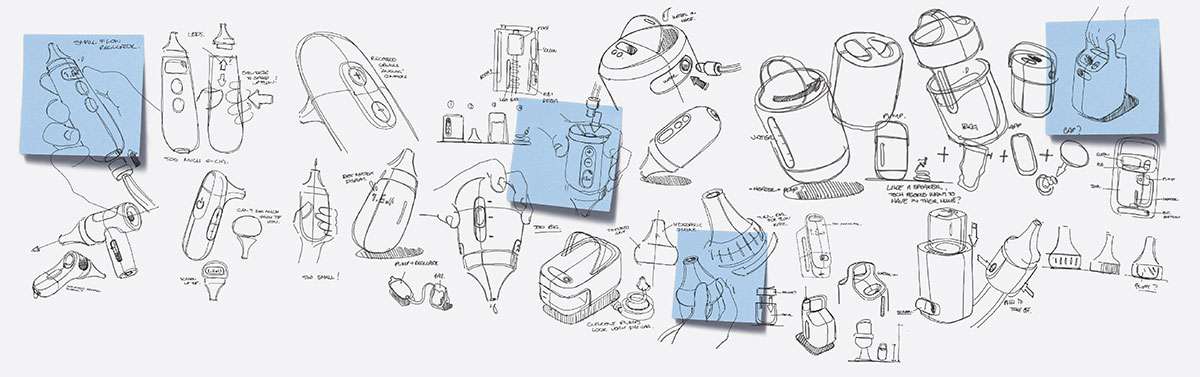

Sketch Ideation early on in the project, initially the design focussed on irrigating with a mechanical solution, as the project progressed, portability became a main focus and the belt design direction was selected.

During the project I developed a set of fabric patterns and once the design was finalised I spent two days working with Thread Design in Cardiff, manufacturing the design. To then test with my champion user and validate the design intent.

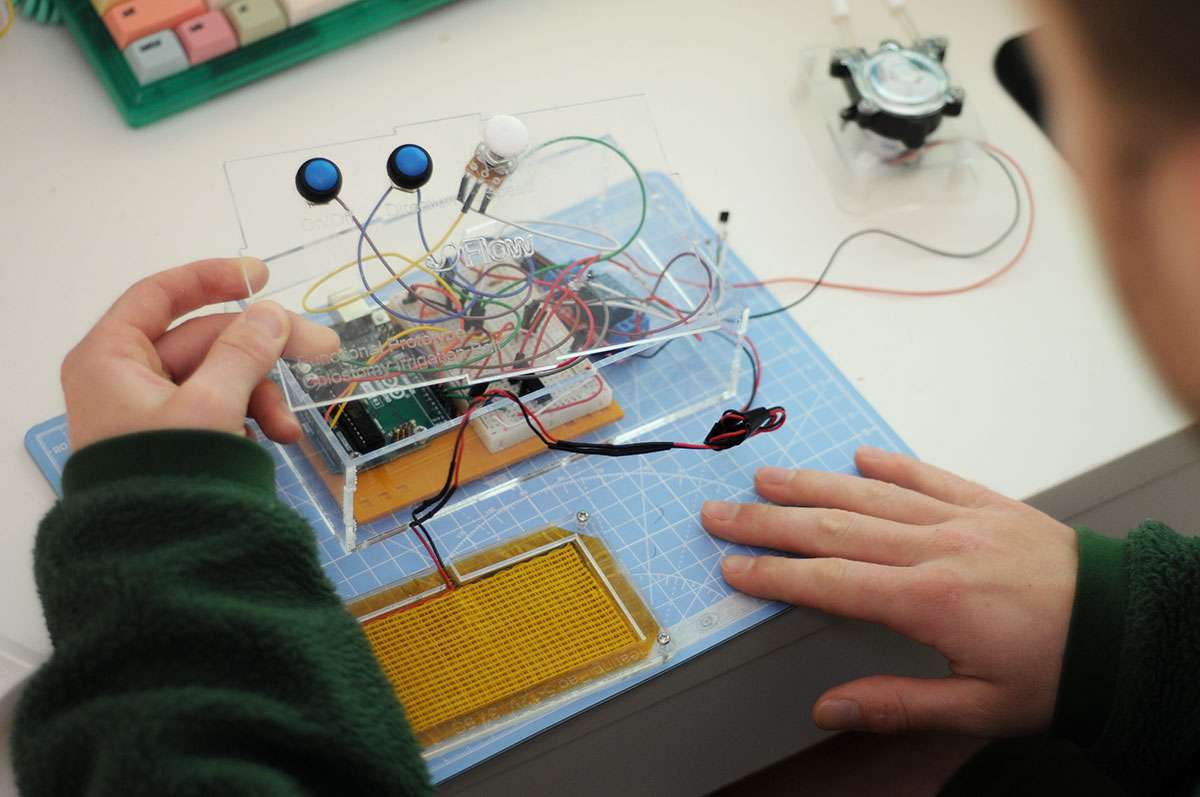

An Arduino was used to build and code a functional prototype to test and evaluate the design, helping to define its limitations.

I was fortunate enough to spend my placement year working at Cambridge Consultants, where I got to work on a number of projects spanning healthcare, consumer and the industrial space. This experience has greatly influenced me as a designer, and getting to work as part of a multidisciplinary team really challenged and improved me as a designer, but also as a human being.