Jacob Das

My name is Jacob, I'm a creative Product Designer who loves solving tough design and manufacturing problems and bringing both my own and others' ideas to life.

My name is Jacob, I'm a creative Product Designer who loves solving tough design and manufacturing problems and bringing both my own and others' ideas to life.

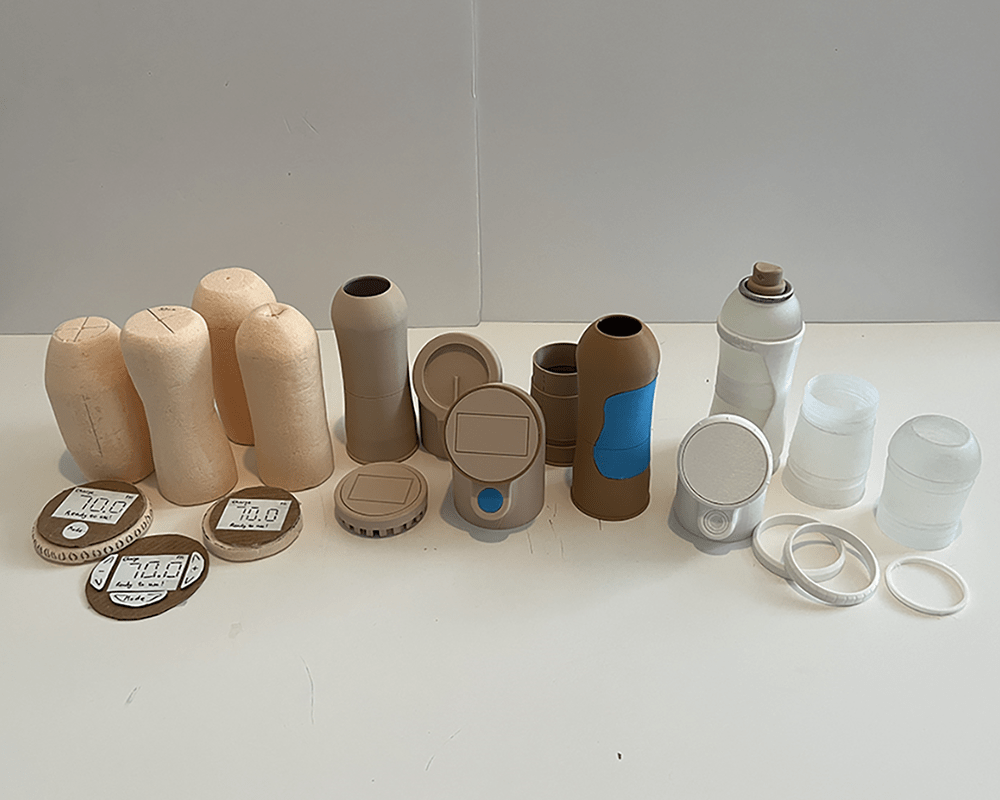

reFresh is a reusable, refillable and rechargeable aerosol can that aims to reduce the impact of personal care aerosol products on indoor air quality and the surrounding environment.

Aerosol products now release more Volatile Organic Compounds into the atmosphere than cars.

The vast majority of which come from personal care aerosol products. This is only increasing along with the demand for aerosolised products, particularly in developing countries.

In developed countries, the average consumer uses 10 aerosol cans per year. Often releasing the chemical propellants inside small, poorly ventilated areas inside their homes.

Whilst aerosol alternatives do exist, they are far from perfect. Many people want to reduce their aerosol usage but find non-aerosolised options off-putting – whether it’s the long time to dry, the sticky residue, or the wet application. The truth is simply that the convenience and performance of aerosols for personal care cannot be beat.

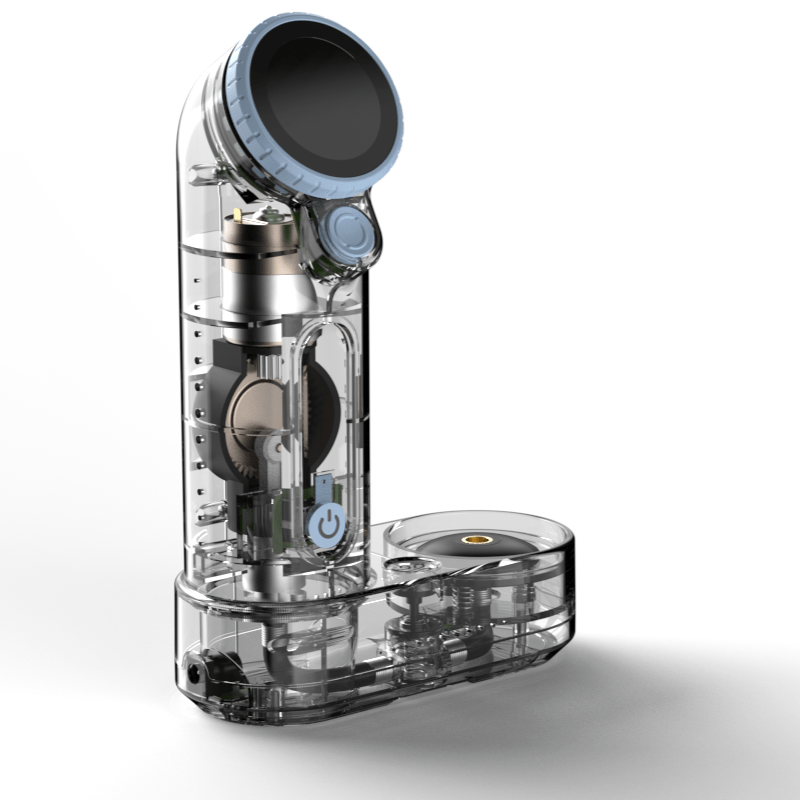

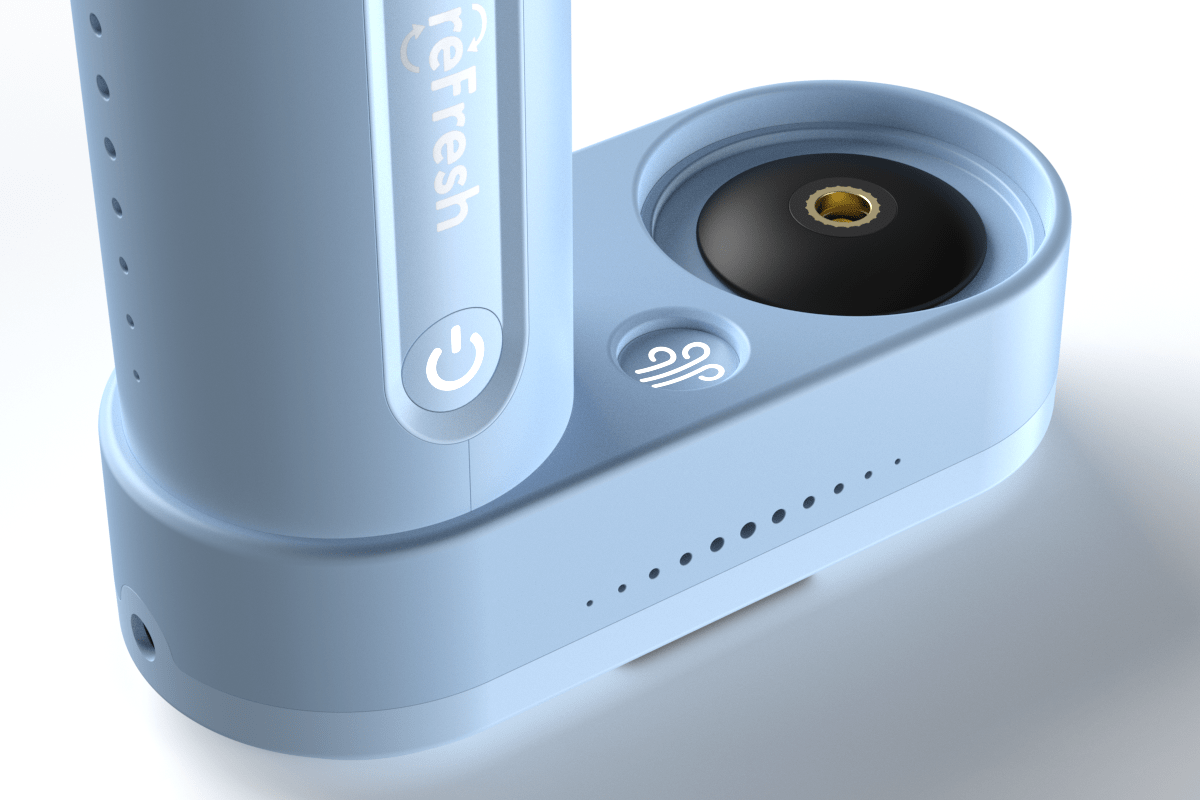

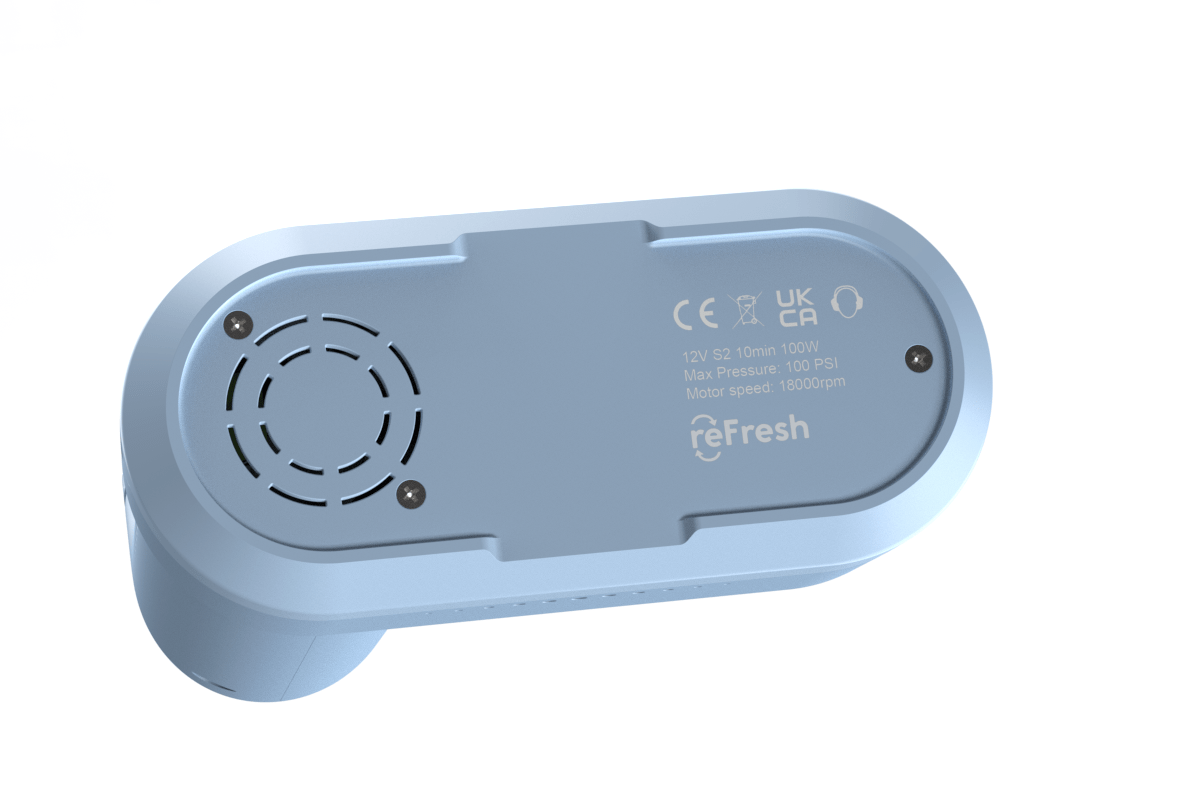

This is where the reFresh aerosol can comes in. Using a valve in the bottom of the aerosol can, it can be charged with compresed air from the stand – allowing it to constantly be topped up to a high pressure for atomisation, using compressed air instead of harmful VOCs. The aerosol can unscrews in to two halves, allowing the user to refill or replace the liquid product inside.

The aerosol can comes with a soft rubber cover. The purpose of this is to not only provide added comfort, but to prevent unintentional or absent-minded opening of the aerosol can before it has been depressurised.

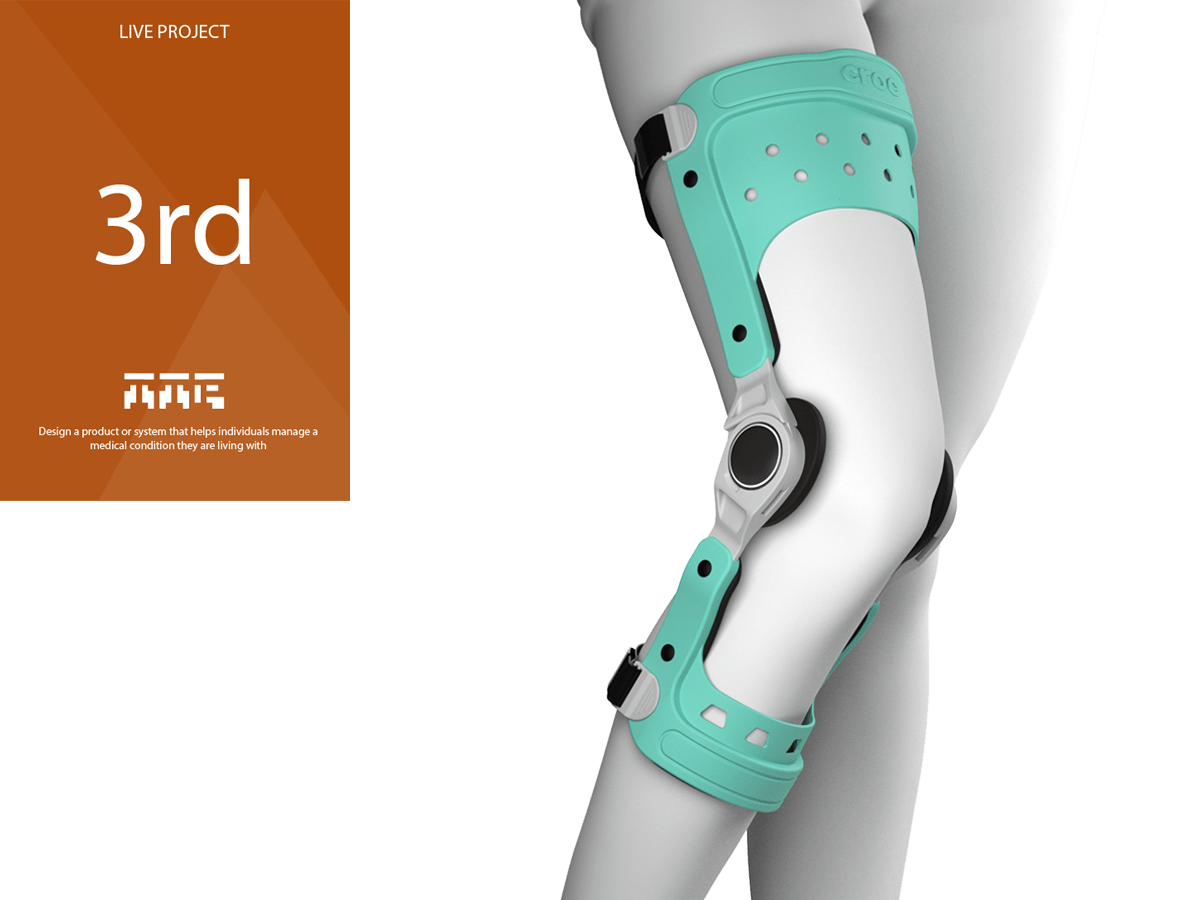

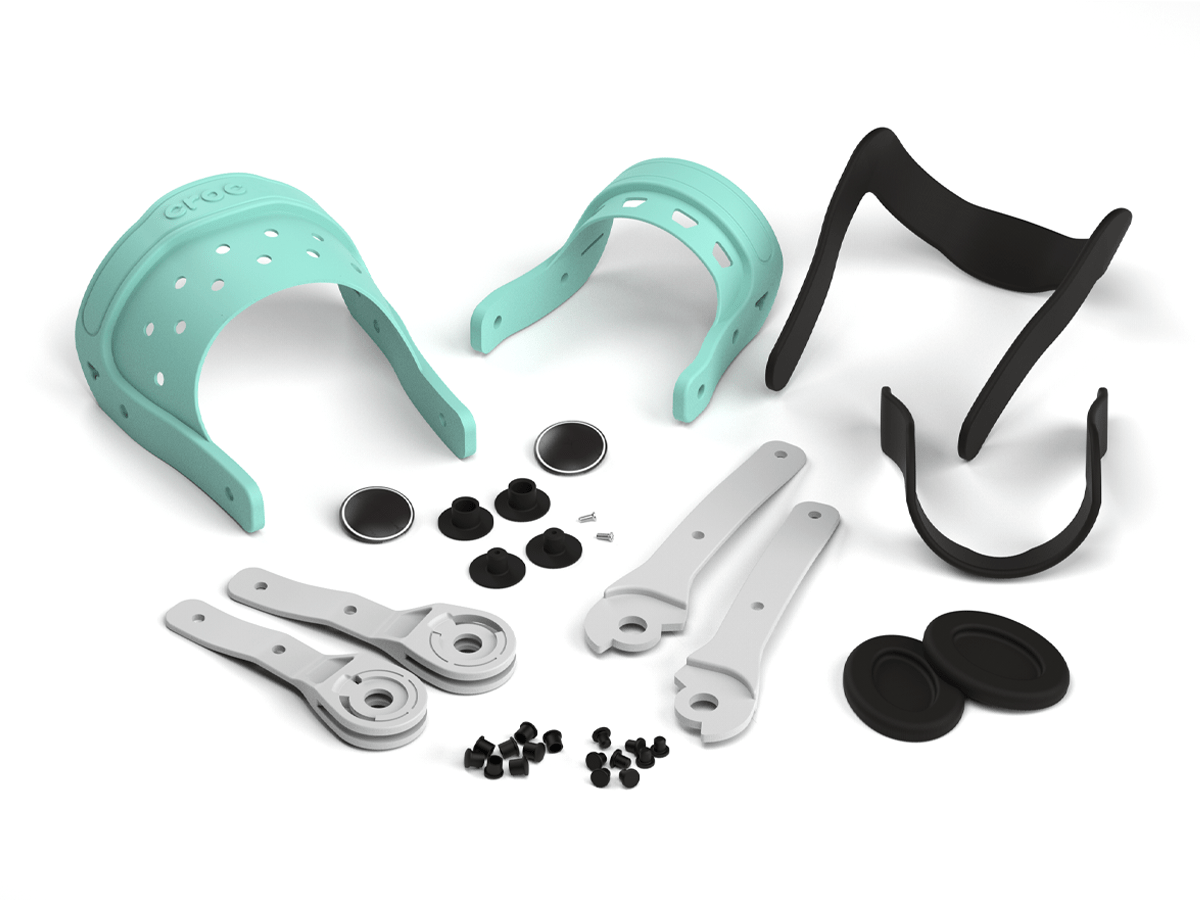

Live projects is a 10 day design sprint with briefs set by external companies. For this project I followed the brief set by TTP: ‘Design a product that helps individuals manage a medical condition they are living with’ – considering geography and using a non-medical brand.

The design of the removable hinges mean they stop extension at 90* flexion and 10* extension – reducing risk of hyperextension.

Placement year at Lifemarque ltd.

I spent my placement year at Lifemarque ltd. working in the 4 encompassing brands (Lifesystems, Lifeventure, LittleLife and Mountain Paws) but primarily creating products for Lifesystems and being in-charge of re-inventing the Mountains Paws brand.