Aysha Alaa Arif Batayneh

I am a creative and outgoing designer who enjoys coming up with user-centred solutions to improve everyday life. Through blending aesthetics with functionality I am passionate about transforming ideas into feasible products.

I am a creative and outgoing designer who enjoys coming up with user-centred solutions to improve everyday life. Through blending aesthetics with functionality I am passionate about transforming ideas into feasible products.

In third world countries, there is a massive strain on resources; electricity, water, food and other necessities, which is only made worse by the rise of global inflation rates. Camps and off-the-grid communities are rapidly rising, while resources are draining exponentially.

With a rise in farming and alternative lifestyles, new solutions are required to support and better the lives of those with limited access to consistent supplies and resources.

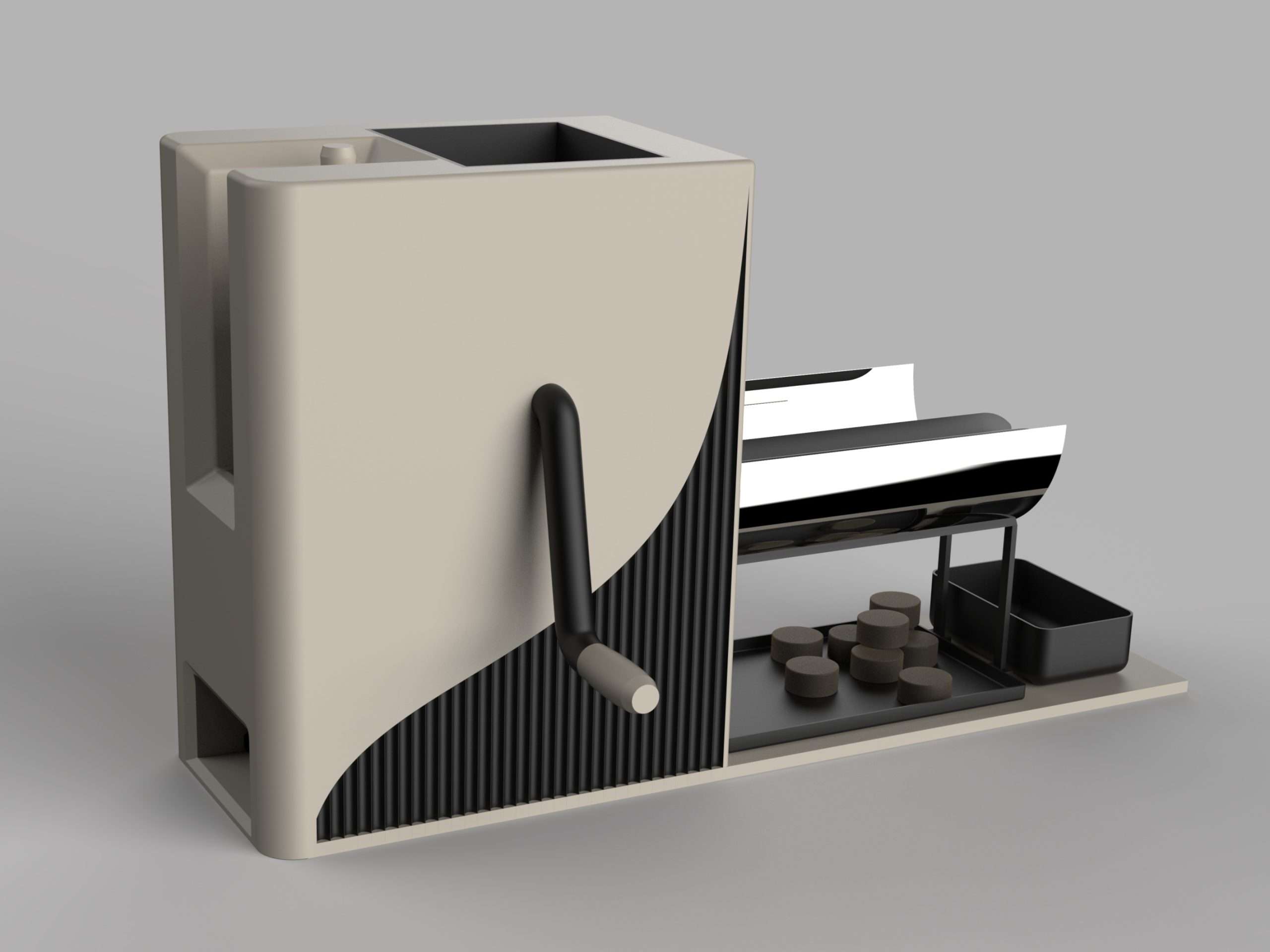

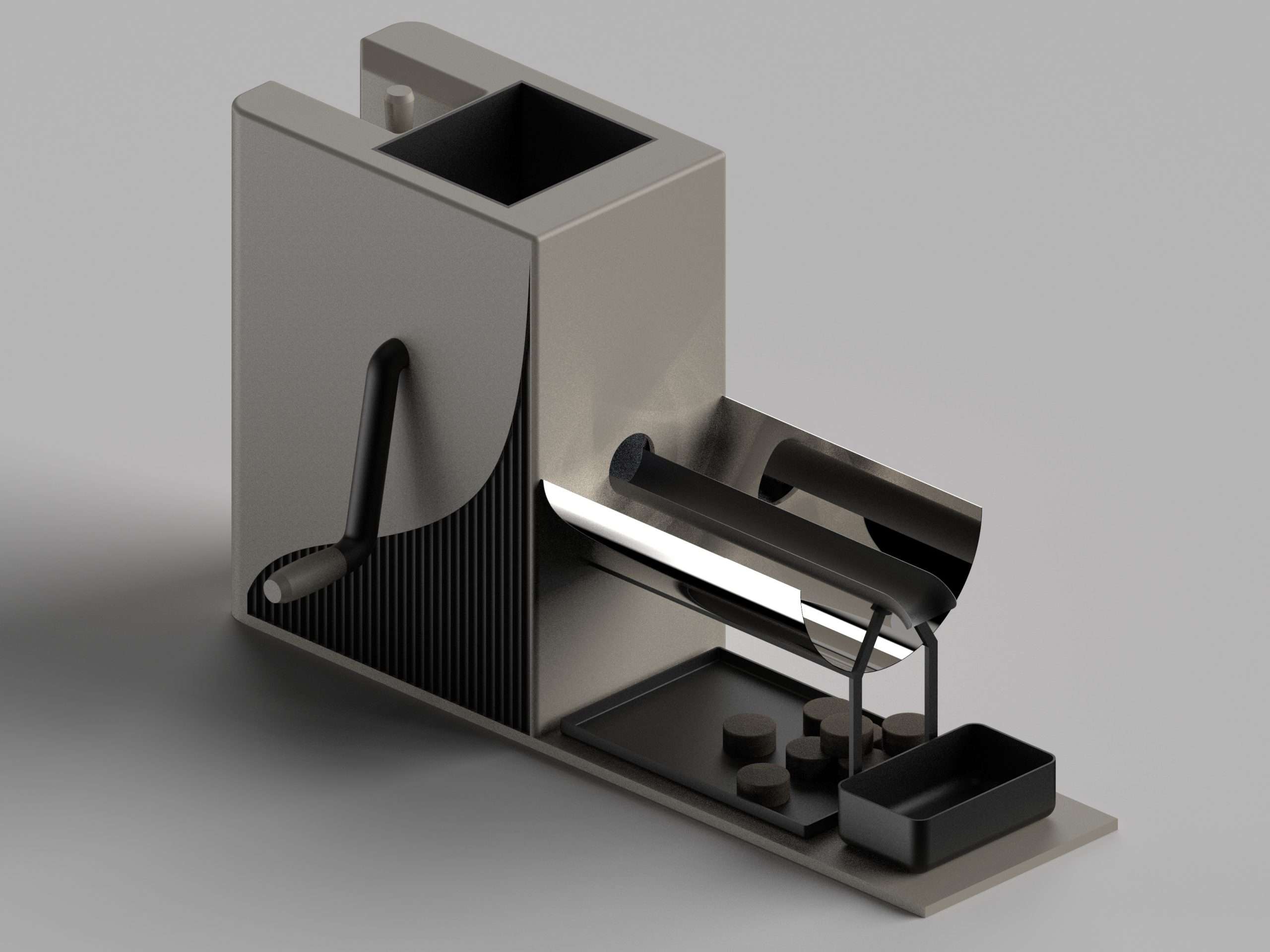

For my final year project I created a machine that aims to repurpose food waste (biomass) in low resource environments, into a source of renewable energy.

Through grinding, drying and moulding, food waste can be processed into multipurpose biofuel briquettes that can be used as a source of kindling or fuel (through burning) as a cleaner method of energy production around the household, or as a nutrient brick for farming and gardening.

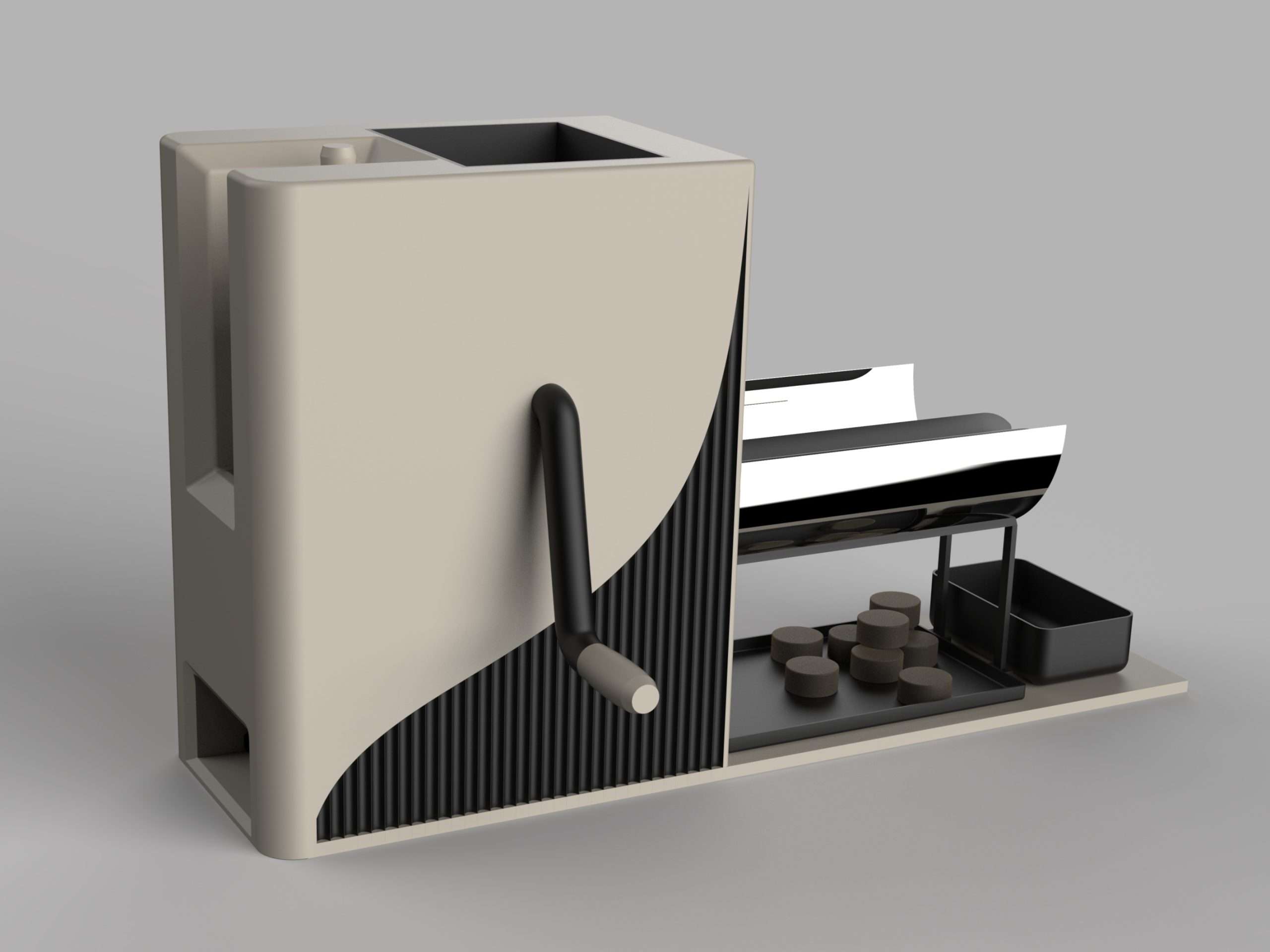

Nara is designed to encapsulate and streamline the process to make it as intuitive as possible for a potential user. A simple grinding mechanism is incorporated to reduce the initial size of the food waste.

Once grinded, waste is spread out manually along a matte black half pipe surrounded by an aluminium solar reflector, therefore enhancing the solar energy creating a powerless oven, speeding up the drying process.

Finally, the dried biomass is collected in a bin then poured into a moulding mechanism operated by a simple pull down lever, therefore creating the end result – a ready briquette!

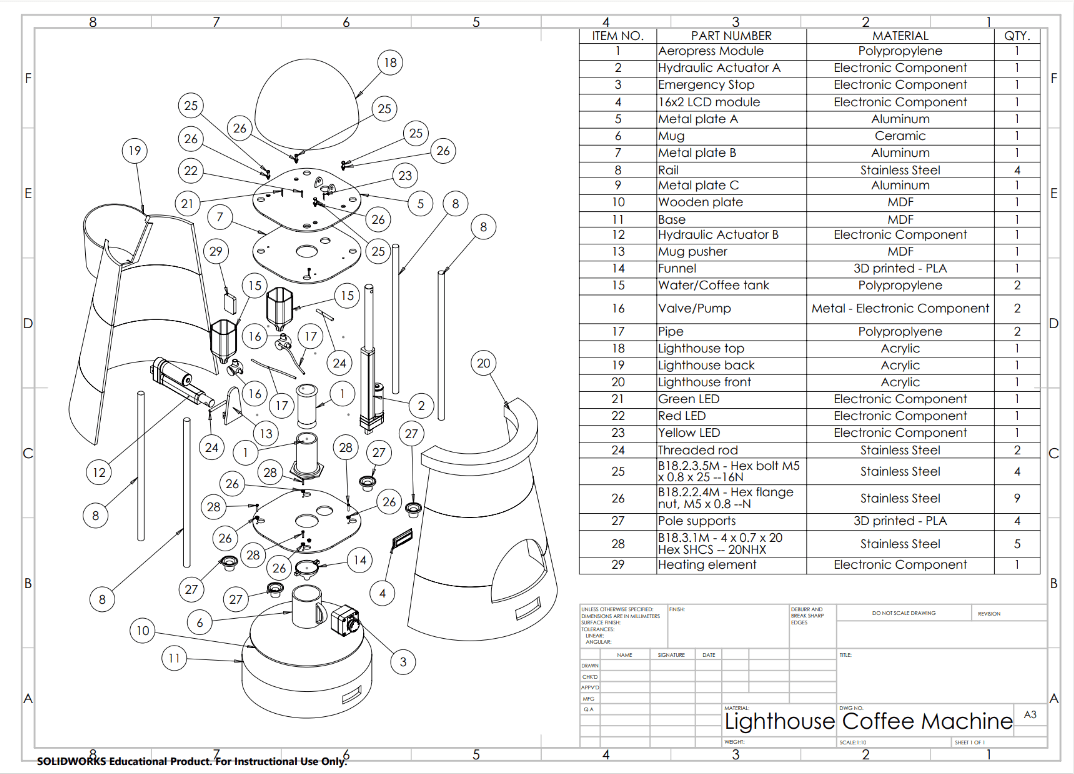

Inspired by the AeroPress coffee machine, as a group we were tasked to design, develop, test, manufacture, analyse and evaluate a fully functional automated electromechanical machine to house the AeroPress components.

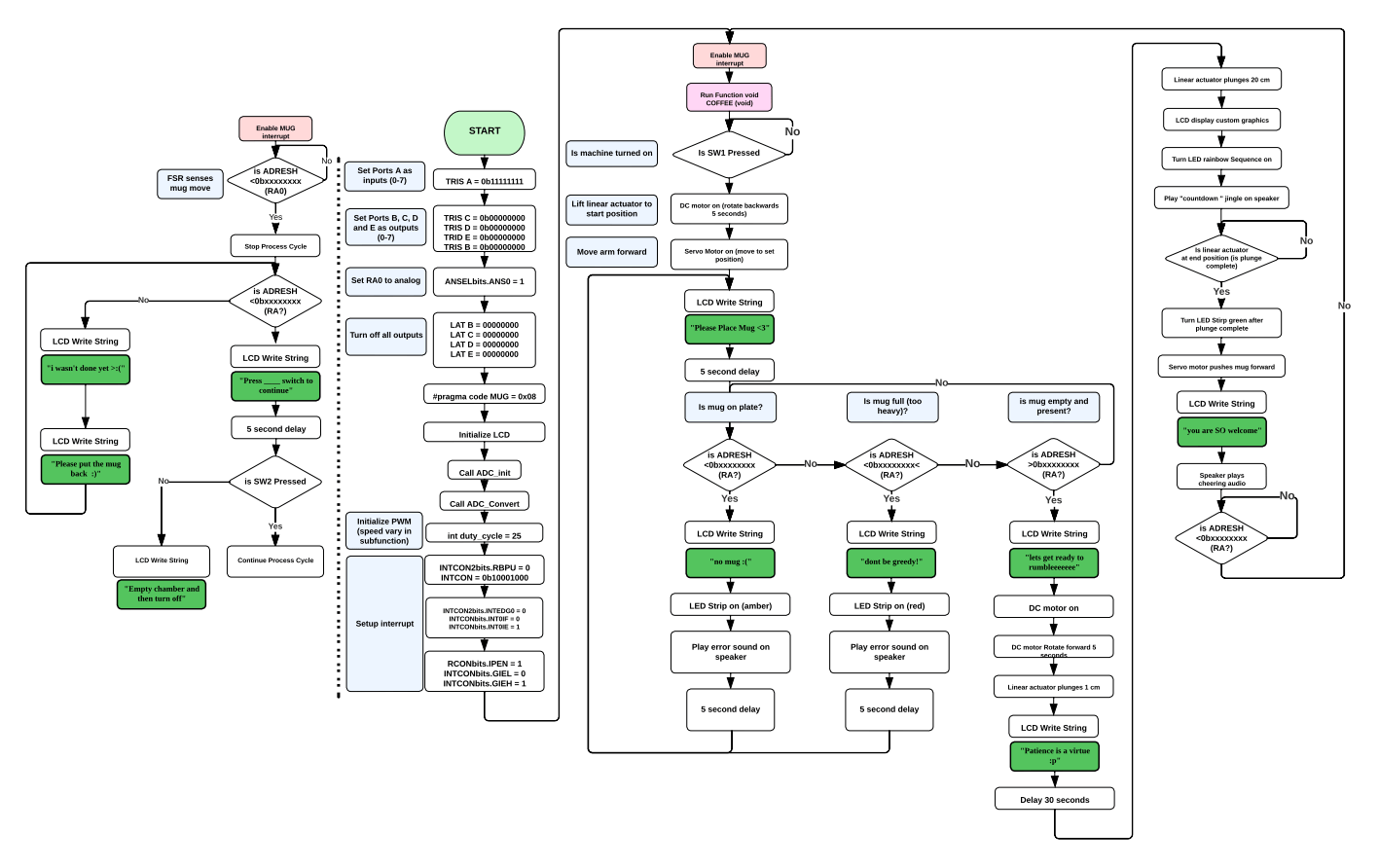

The key features of our coffee machine include the ability to detect whether a mug is present or not, an automated arm pulling the mug into the body of the machine, an incorporated steep timer, a drip prevention mechanism and custom graphics.

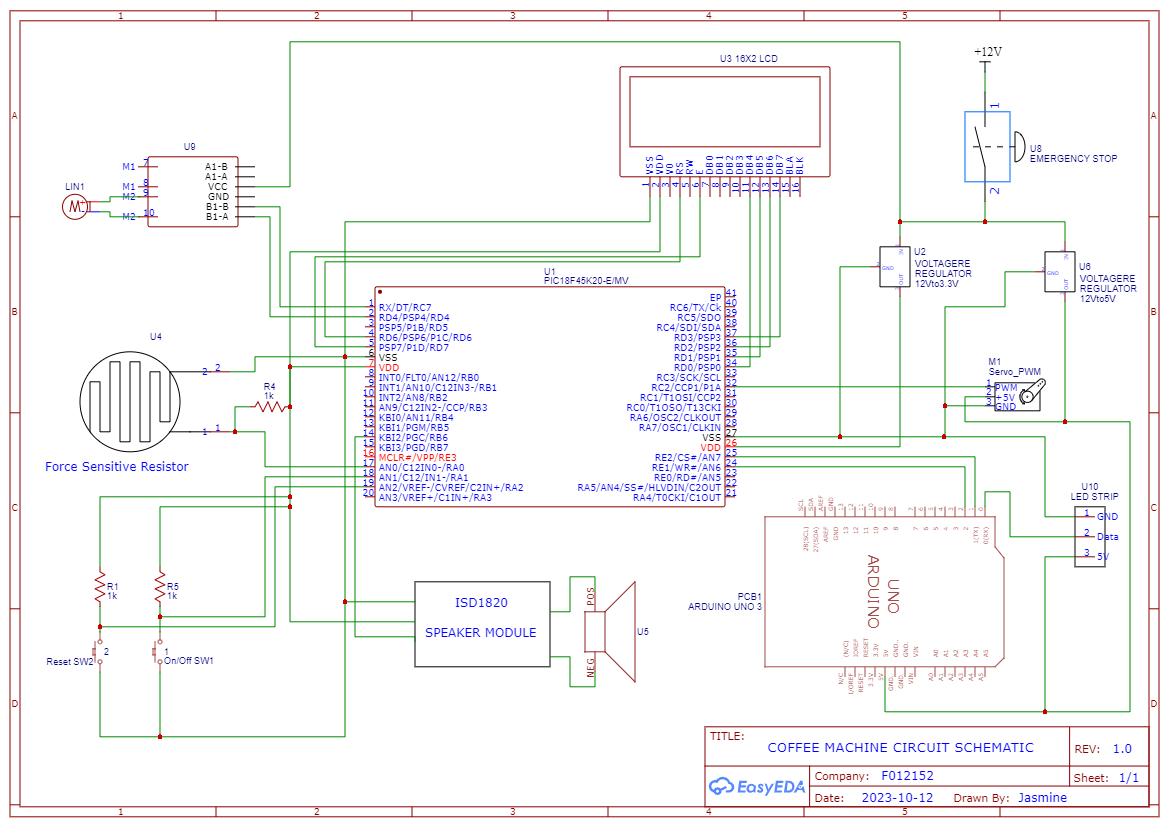

Electrical components were connected to a PIC18F45K20 microcontroller and programmed in C using MPLAB, with an incorporated Arduino Uno. Once the mug is placed on the machine there is no further human interaction, so is a fully automated process.

Calculations and testing allowed for correct selection of materials and dimensions. Creating engineering drawings for each part allowed us to easily build them in the workshop and fully assemble the machine.