Aaron Abraham

From a young age, I've always been passionate about the environment, motivating me to design sustainable products that significantly reduce ecological footprints and inspire others towards greener paths.

From a young age, I've always been passionate about the environment, motivating me to design sustainable products that significantly reduce ecological footprints and inspire others towards greener paths.

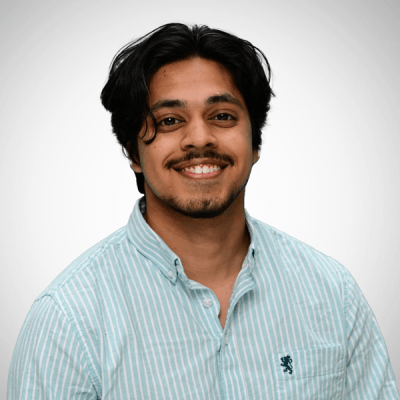

Aeras is an innovative cooling system engineered for construction workers in the extreme high temperature climates of the Middle East. Delivering high air velocity of approximately 10 m/s directly to the neck, Aeras efficiently reduces core body temperature, one of the most crucial areas for thermal regulation.

For enhanced relief, the system features a “cooling mist” effect, offering extra cooling power when urgently needed.

Additionally, Aeras is equipped with heat stress monitoring capabilities to promptly alert users of potential heat stress, ensuring safety and comfort in extreme conditions.

By using a Maxon EC 45 Flat motor, capable of reaching 10,000 rpm, the Aeras cooling system utilizes a design inspired by jet engines, employing Bernoulli’s principle to accelerate the air flow up to 10 m/s. Additionally, the system integrates an impeller, which amplifies the air speed, ensuring an exceptionally high air velocity for effective cooling.

The Aeras cooling mist system incorporates a piezoelectric transducer to agitate water from a 200ml reservoir at a frequency of approximately 2.4 MHz. This high-frequency vibration produces ultra-fine water droplets that form a refreshing mist, delivering enhanced cooling on demand.

To enhance user safety, the Aeras system includes a wearable wristband equipped with sensors for heart rate, skin temperature, and ambient temperature. This data is analyzed using a personalized algorithm to monitor and predict potential heat stress levels.

Should vitals approach critical thresholds, the wristband will pulse to alert the wearer. Failure to respond or reduce heat stress within five minutes triggers an automatic notification to supervisors and emergency responders, ensuring prompt medical intervention.

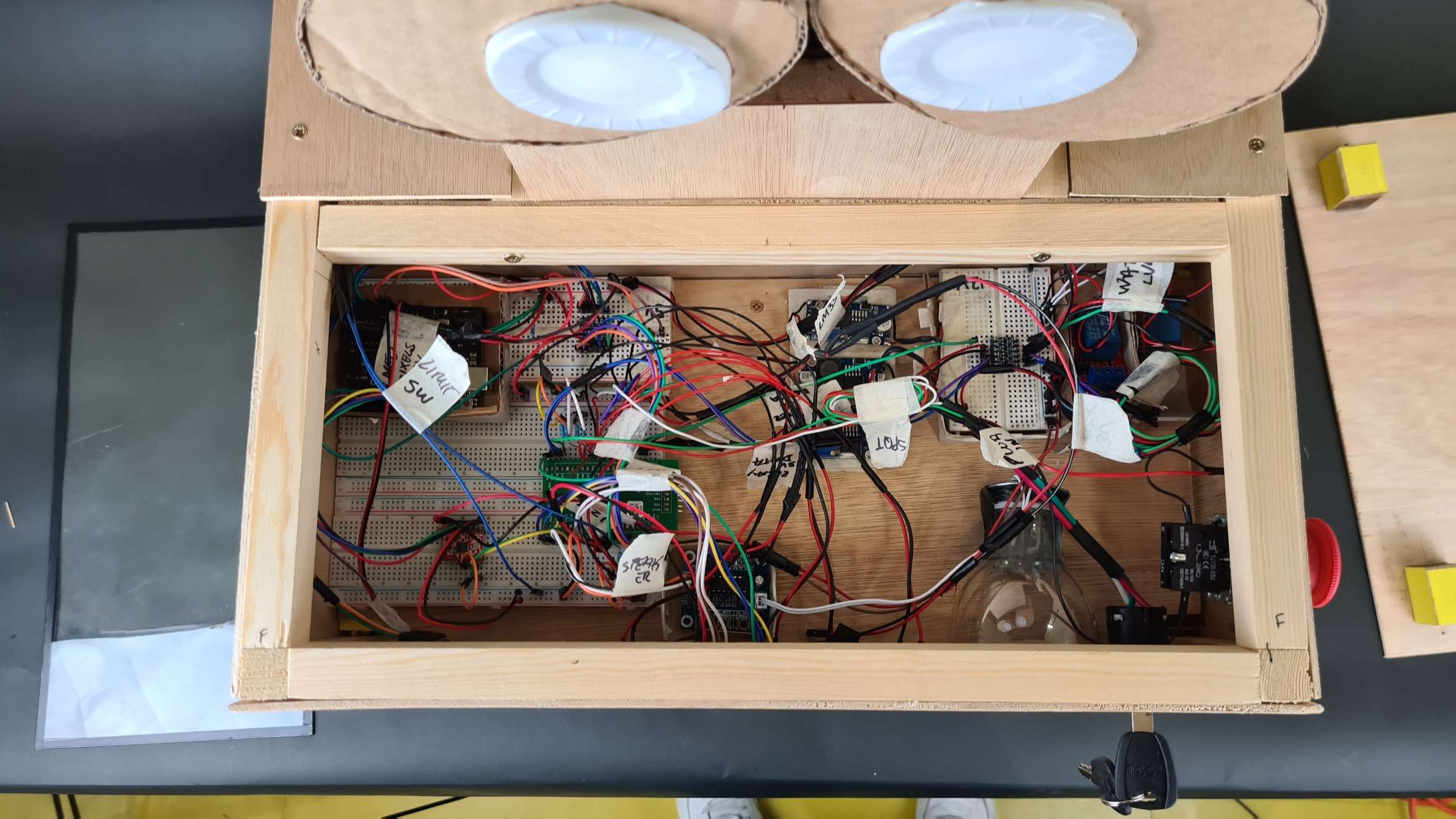

Tasked with Designing and manufacturing an automated AeroPress machine that can produce at least 3 cups of customized coffee.

The COFF.E incorporates a user-friendly menu selection and ignition switch to help users customize their coffee to their desire.

Additionally, the implementation of NFC and a speaker system, both connected through an Arduino, contributes to improving the overall functionality.

The inclusion of a variety of operational sensors further enhances the machine’s efficiency and safety, preventing accidental misuse and ensuring longevity in the system’s operation.

Moreover, a robust plunging rig which consistently plunges as desired, before automatically resetting to limit user interactions required was developed.

Finally, inspired by Disney’s Wall-E character, Neo-pixel LED rings to emulate expressive eyes were included, a testament to the product form and function.

worked in a R&D department which specialized in Ergonomics, High-Quality Feel (HQF) and Seat Comfort. Focused particularly in HQF related tasks where vehicles and designs were evaluated and tested from an engineering perspective.

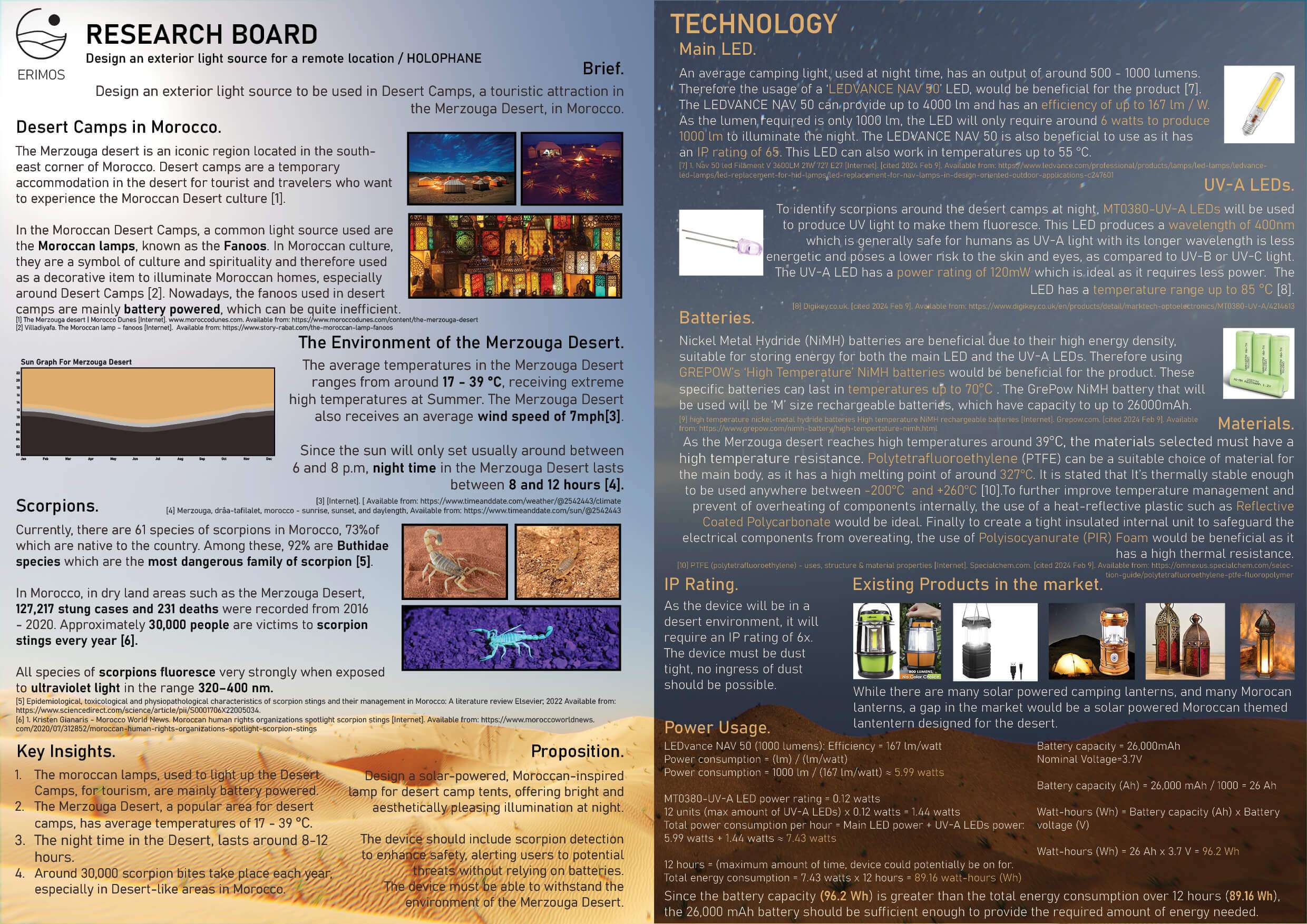

Awarded 1st place by Holophane Europe and the Lighting Industry Association for Loughborough live projects – One Week Design Sprint Project, Erimos.